| ROHMís Isolated DC-DC Converters for xEV Reduce Application Size and Efforts for Noise Design Countermeasure |

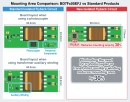

| Contributes to smaller mounting area in isolation circuit by 30% compared with standard products |

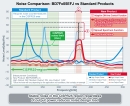

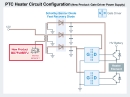

| Willich-Münchheide, Germany, January 25, 2023 Ė ROHM has recently developed an isolated flyback DC-DC converter, BD7Fx05EFJ-C (BD7F105EFJ-C, BD7F205EFJ-C) optimized for gate driver power supplies in xEV applications such as electric compressors, and PTC heaters. (Fig. 1) In recent years, xEVs such as hybrid and electric vehicles have become increasingly popular as the industry moves towards achieving a sustainable society. xEVs, which primarily use electricity as their energy source, are equipped with unique applications such as, electric compressors for AC, and PTC heaters to raise the cabin temperature. And as these applications are driven by high voltages, it is necessary to isolate the primary circuit that includes the battery from the secondary circuit comprised of the motor and other systems to ensure safety. However, in addition to issues such as larger mounting area and power consumption, conventional isolated circuit configurations require considerable noise countermeasures for switching frequencies that vary with output current. ROHMís new product utilizes a circuit configuration that achieves stable switching frequency characteristics without requiring a photocoupler, decreasing application size together with workload for noise design countermeasure. Leveraging ROHMís superior analog design technology allows the BD7Fx05EFJ-C to eliminate the need for photocouplers, transformer auxiliary windings, and peripheral components conventionally necessary to detect secondary-side voltage and current. On top, next to solving issues with photocouplers, such as large power consumption, fluctuating detection accuracy due to temperature, and deterioration over time, ROHM has also achieved greater miniaturization by reducing the number of components. As a result, it is possible to reduce the number of components Ė including the photocoupler Ė used for current detection by 10 (equivalent to a board area of 30%) compared to general isolated flyback power supply circuits. The BD7Fx05EFJ-C is also equipped with an adaptive ON-time control function that fixes the switching ON time, ensuring a stable frequency of around 350kHz regardless of output power. To be compliant with the CISPR25 automotive EMC standard requires considerable noise design in the frequency range from 150kHz to 300kHz, but as ROHMís new converters do not fall within this band, noise countermeasures can be greatly simplified. This, together with a spread spectrum function that minimizes radiated noise, contributes to reducing the number of efforts for noise design. Going forward, ROHM will continue to develop products that contribute to greater miniaturization and lower noise by leveraging its strength in analog technology, helping to achieve a sustainable society. (Fig. 2 + 3) Product Lineup In addition to reducing the number of components and person-hours required for noise countermeasures, the BD7Fx05EFJ-C improves application reliability by incorporating multiple protection circuits along with a function that stabilizes the output voltage. (Fig. 4) Application Examples ROHMís new DC-DC converter IC is ideal for gate driver power supplies that must be isolated from the battery for safety. Automotive: electric compressors, PTC heaters, inverters Industrial: Power supplies, PLC (Programable Logic Controller), inverters (Fig. 5 + 6) Online Sales Information Availability: Now (in mass production) Online Distributors: Digi-Key, Mouser, and Farnell Scheduled for release at other online distributors as well. Product Information Applicable Part Nos: BD7F105EFJ-CE2, BD7F205EFJ-CE2 Evaluation Board information (Fig. 7) Evaluation Board Part Nos: BD7F105EFJ-EVK-001, BD7F205EFJ-EVK-001 |

| About ROHM Semiconductor ROHM Semiconductor is a global company of 452.1 billion Yen (3.3 billion Euros) per March 31st, 2022, with over 23,000 employees. The company develops and manufactures a very large product range from SiC Diodes and MOSFETs, Analog ICs such as Gate Drivers and Power Management ICs to Power Transistors and Diodes to Passive Components. The production of our high performing products is taking place in state-of-the-art manufacturing plants in Japan, Germany, Korea, Malaysia, Thailand, the Philippines, and China. ROHM Semiconductor Europe has its Head Office near Dusseldorf serving the EMEA region (Europe, Middle East, and Africa). For further information, please contact www.rohm.com |

| Press Releases online: | 4517 |

| Press Releases | | | Newsletter | | | Search | | | Agency | | | German |