| New faster 125°C operation compatible EEPROMs extend service life |

| Reducing initial data writing time by 30% and shortening time-to-shipment |

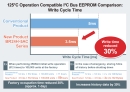

| Willich-Münchheide, Germany, January 14, 2021 Ė ROHMís newly introduced 125°C operation compatible I²C bus EEPROMs, BR24H-5AC series targets applications that require data storage under harsh environments, such as factory settings for onboard cameras and sensors, airbag operating history, and data logging for always-on operating industrial automation systems and servers. (Fig. 1) The BR24H-5AC series of 125°C operation compatible EEPROMs is the first in the industry to achieve a writing time of 3.5ms by implementing original data writing and reading circuit technology, reducing writing time by 30% compared to the 5ms of conventional products. Additionally, in contrast to standard products capable of just 1 million rewrites, the BR24H-5AC series guarantees up to four million writing cycles by data endurance, which not only extends application service life, but is ideal for data loggings requiring frequent data rewrites. In the automotive and industrial equipment sector, safety and traceability requirements make it necessary to store the operating history in non-volatile memory in the system. Among these, EEPROMs are typically adopted over other types of non-volatile memory such as flash memory in applications that require high reliability, including onboard cameras, airbags, industrial automation systems and servers, due to their ability to reliably write and store data under harsh conditions. As a leading semiconductor manufacturer with over 20 years of experience in developing EEPROMs, ROHM offers high quality products that have been well-received in the automotive, industrial equipment, and consumer markets by leveraging proprietary high reliability memory cell technology. This latest series of I²C bus EEPROMs is designed to reduce process time before factory shipment in automotive and industrial equipment applications. ROHM is committed to contributing to reduction of process time during factory shipment along with greater application reliability by developing SPI bus compatible products while continuing to expand the product lineup by capacity. (Fig. 2 + 3) BR24H-5AC Series Lineup (Table) Application Examples - Storing factory settings (e.g. onboard cameras) for ADAS - Ignition ON/OFF history - Cluster mileage display - Operating history (e.g. airbags), emergency data logging - Retaining settings for car navigation/audio - Data logging for industrial automation systems ...and other systems requiring high reliability data retention over a long period of time. Pricing: 0.6USD/unit (samples, excluding tax) Availability: In mass production |

| About ROHM ROHM Semiconductor is a global company of 3.326 billion US dollars per March 31st, 2020 with 22,191 employees. The company develops and manufactures a very large product range from the Ultra-Low Power Microcontroller, Power Management, Standard ICs, SiC Diodes, MOSFETs and Modules, Power Transistors and Diodes, LEDs to passives components such as Resistors, Tantalum Capacitors and LED display units, thermal Printheads. The production of our high performing products is taking place in state-of-the-art manufacturing plants in Japan, Korea, Malaysia, Thailand, the Philippines and China. LAPIS Semiconductor (former OKI Semiconductor), SiCrystal GmbH and Kionix are companies of the ROHM Semiconductor Group. ROHM Semiconductor Europe has its Head Office near Dusseldorf serving the EMEA region (Europe, Middle East and Africa). For further information, please contact www.rohm.com/eu |

| Press Releases online: | 4653 |

| Press Releases | | | Newsletter | | | Search | | | Agency | | | German |