| ROHM's New High-Reliability 1608-Size White Chip LED |

| Contributes to the Long-Term Design Quality of Displays in Industrial and Consumer Applications |

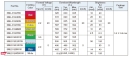

| Willich-Münchheide, Germany, February 21, 2019 – ROHM today announced the availability of the SMLD12WBN1W, a White chip LED with 1608 (1.6x0.8mm) size that achieves class-leading reliability. This new package offers superior mountability and long operational life, which makes it ideal for use in display panels (e.g. temperature control displays) in industrial and compact consumer equipment. In recent years, the need to improve both design quality and visibility of industrial equipment has increased the use of compact White LEDs for numerical displays and visual indicators in these applications. High-reliability LEDs are required to guarantee no degradation in luminosity even with continuous operation for over 10 years. However, achieving this has not been possible until now due to the use of epoxy or silicone resins for molding of typical White chip LEDs. These types of material could not provide enough reliability to prevent degradation in luminosity or provide enough package strength to facilitate mounting on circuit boards. ROHM has been providing 1608-size chip LEDs in colors ranging from Red to Green, and now it is adding White to this product range to meet market demand. The adoption of a new material that combines the benefits of epoxy and silicone resins made it possible to achieve class-leading reliability of White chip LED in such a small package. ROHM’s tests have demonstrated that the SMLD12WBN1W maintained 100% of its luminosity after operating for 1,000 hours (@25°C, IF=20mA). This represents an improvement of 20x in operational life when compared to other similar products available in the market. Additional tests showed that the package strength was improved 25 times with the new material when compared to products using silicone resin. This will contribute to significantly reducing the occurrence of failures during fabrication when mounting on circuit boards. ROHM is committed to continue developing highly reliable LEDs and to strengthen its product lineup while focusing on increasing usability. (fig. 1) Key Features 1. Successfully maintained 100% luminous intensity during operational testing (25°C, IF=20mA, 1,000hrs) Traditionally, Red and Green LEDs used in display panels of industrial equipment are less prone to cause yellowing of the resin due to light energy. Therefore, luminosity degradation has not been regarded as a problem. Epoxy resins with high mold hardness are commonly adopted for compact molded type LEDs. However, in the case of LEDs with a short wavelength (λD<527nm) such as White, the resin may turn yellow due to the energy of the light. (fig. 2) To address this issue, the SMLD12WBN1W utilizes a new material for the sealing resin that maintains 100% luminosity during operational testing (25C, IF=20mA, 1,000hrs). This results in approx. 20x longer life when compared to the residual luminosity shown under the same conditions by similar products available in the market. 2. 25x higher package strength than those using silicone resin Although light intensity degradation can be improved by adopting silicone resin, the molding becomes easier to detach from the substrate. Measures to enhance mounting strength such as adding reflectors to compact LEDs cannot be used, and damage to the molding section remains a challenge. The use of a new resin material improves the molding strength by 25x when compared to products using silicone resin even at high temperatures (Ta=150C). This minimizes defects during mounting on circuit boards, thus achieving superior mountability. Lineup (fig. 3) |

| About ROHM Semiconductor ROHM Semiconductor is a global company of 397,106 million yen (3,65 billion US$) revenue per March 31th, 2018 with 23,120 employees. ROHM Semiconductor develops and manufactures a very large product range from the Ultra Low Power Microcontroller, Power Management, Standard ICs, SiC Diodes, MOSFETs and Modules, Power Transistors and Diodes, LEDs to passives components such as Resistors, Tantalum Capacitors and LED display units, thermal Printheads in state-of-the-art manufacturing plants in Japan, Korea, Malaysia, Thailand, the Philippines, China and Europe. LAPIS Semiconductor (former OKI Semiconductor), SiCrystal AG, Kionix are companies of ROHM Semiconductor Group. ROHM Semiconductor Europe has its head office near Dusseldorf serving the EMEA region (Europe, Middle East and Africa). For further information please contact www.rohm.com/eu |

| Press Releases online: | 4218 |

| Press Releases | | | Newsletter | | | Search | | | Agency | | | German |